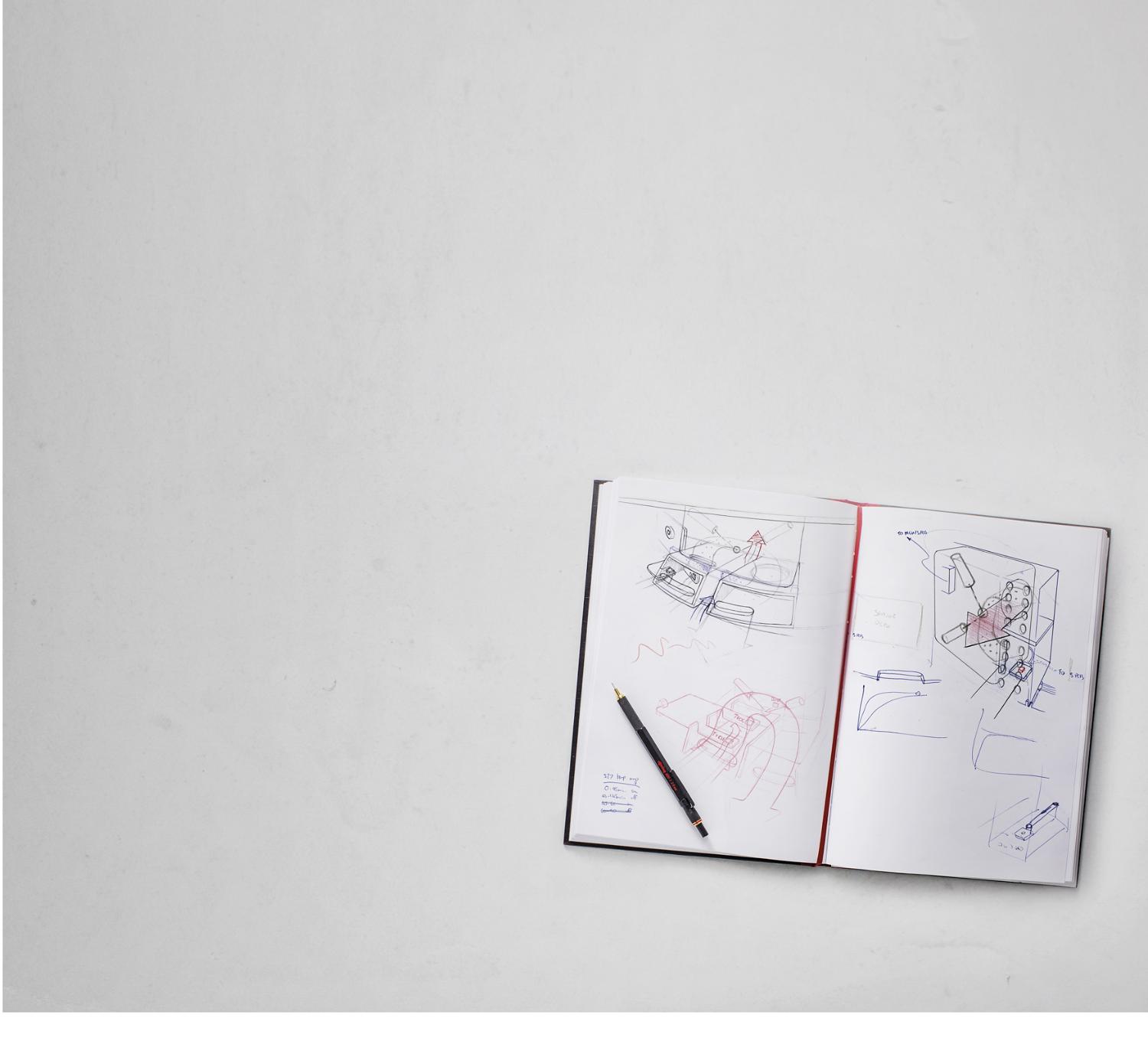

Engineering story

“Multifunctionality shouldn't mean compromise. Dyson technology works properly, without exception.”

James Dyson – Engineer

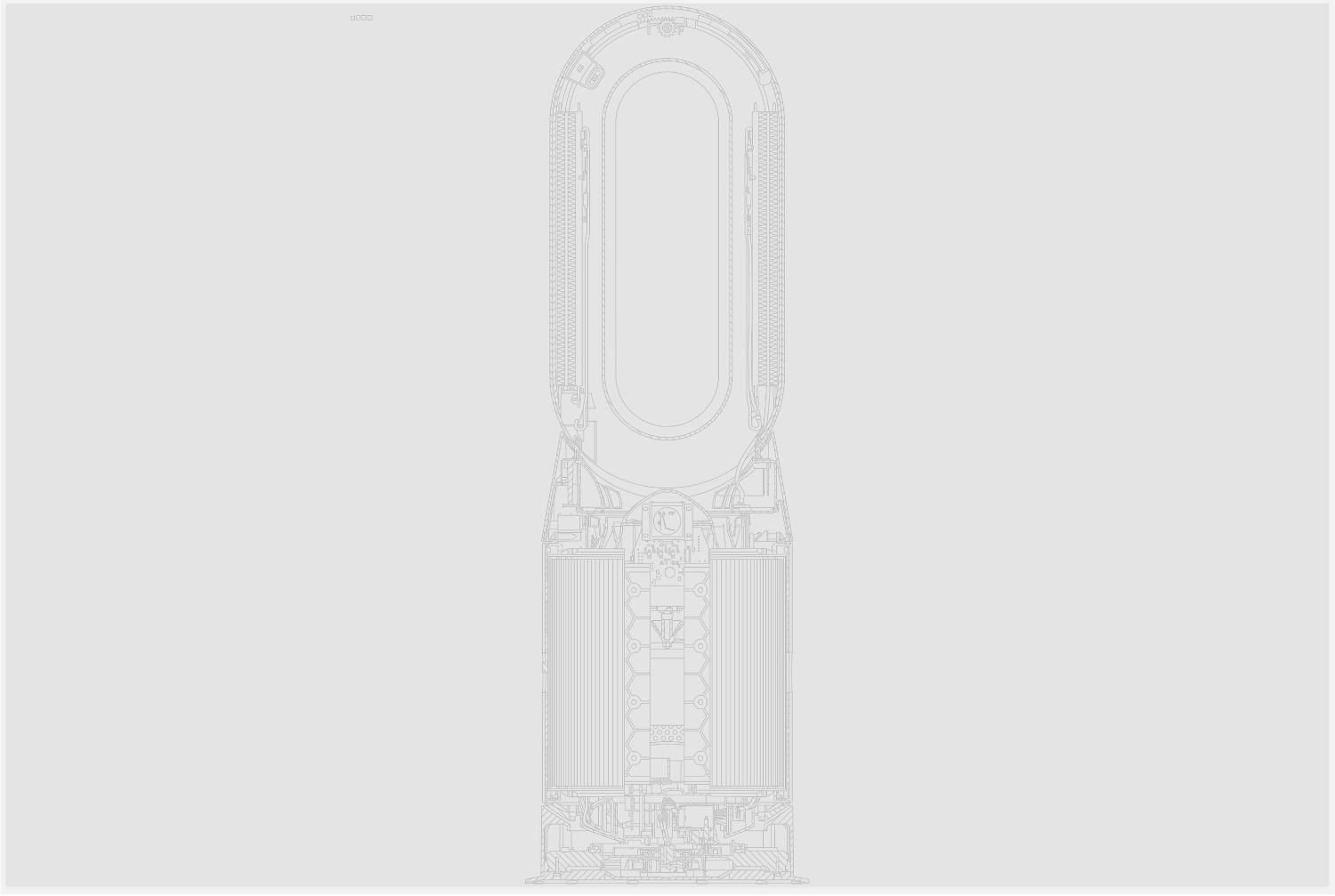

Why Dyson heaters are fast to heat the room evenly

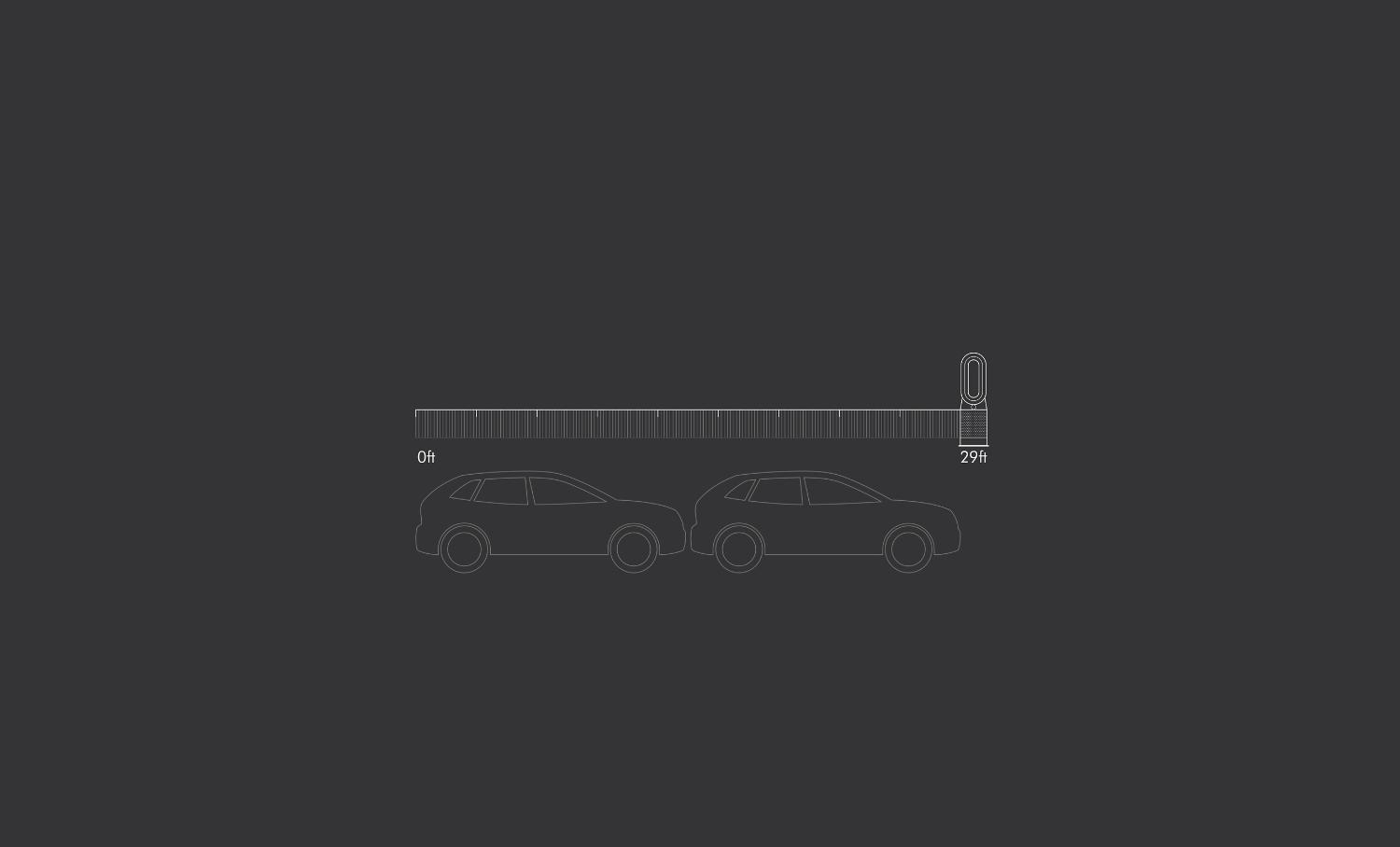

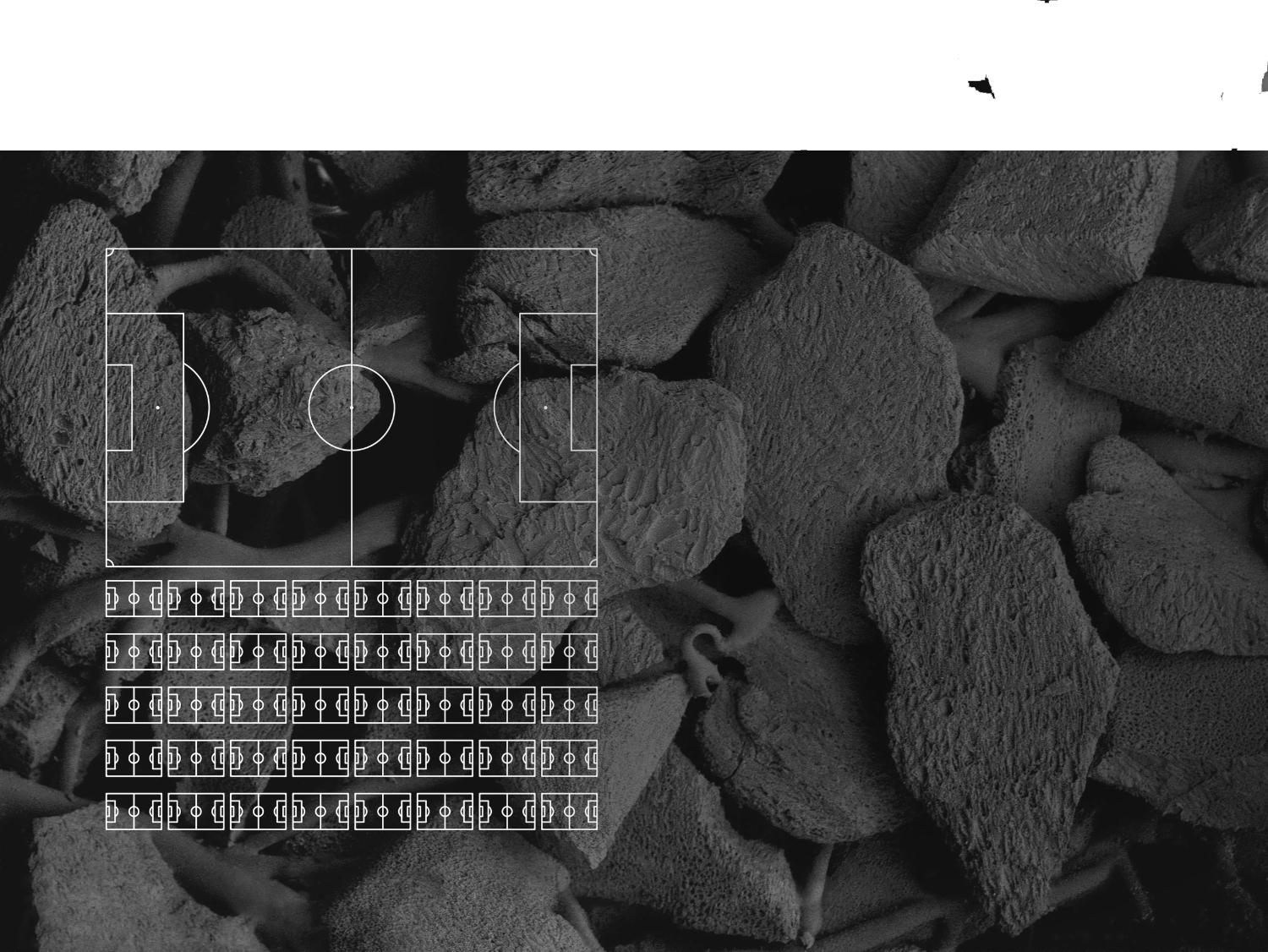

How we pushed beyond industry test standards, to purify every corner of the room¹

-

engineers

-

unique tests

-

heating tests

-

purifying tests

Choose your model

Buy from Dyson.com

¹Tested for air projection (DTM801) and purification coverage in a 81m³ room (TM-003711).